Description of Construction waste crusher production line

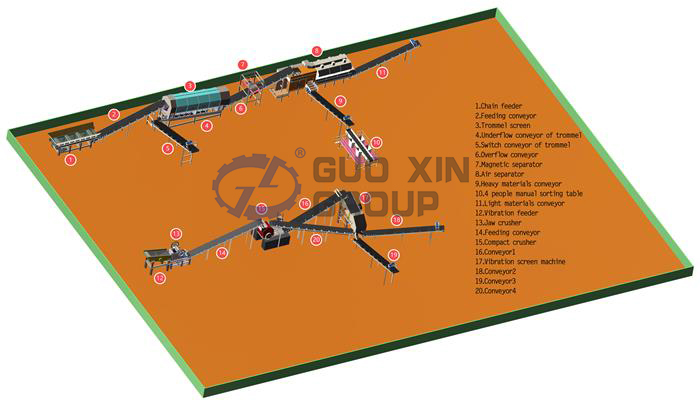

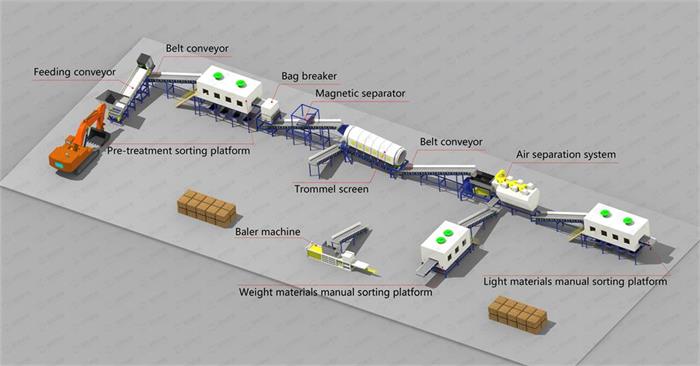

After the mixed construction waste enters the storage bin of the garbage dump, it is fed to the chain plate feeder by a grab bucket or a forklift. The chain plate feeder evenly sends the waste to the drum screen through the belt conveyor for screening. The screen mesh aperture is initially set at 30mm, which can separate the waste into materials smaller than 30mm (mostly sand and gravel) and materials larger than 30mm (wooden boards, light objects, bottles, stones, bricks, etc.). Among them, the screened materials smaller than 30mm are transferred to the temporary storage area for centralized transportation and backfilling or screened into fine aggregate. The sieve materials larger than 30mm are sent to the air separation system by the belt conveyor. After passing through the air separation system, the garbage is separated into light materials (plastics, light combustibles, wood, textiles, etc.) and heavy materials (bricks, stones, and other building aggregates). The light materials are packaged and incinerated after valuable items are recovered. The heavy materials (pure construction waste) enter the manual sorting table to sort out a small amount of debris other than construction waste and then enter the crusher and vibrating screen to be made into building aggregates.

Introduce to Construction waste crusher production line

Guoxin newly-designed garbage separation machine for sale is very necessary for those who want to invest in garbage sorting and recycling. As people focus more on resources, environment, and sustainable development, they’ve concerned more about waste recycling, thus garbage sorting has become a very potential and profitable industry.

Guoxin Newest Construction waste crusher production line

also called garbage sorting machine, which can separate various garbage like urban waste, construction waste, industrial wastes as well as mining waste. We have learned from the advanced waste sorting technology of developed countries and combined our own designs together with the technology to create our own waste sorting machine with high-cost performance. Now this plant has gained a good reputation and sold well in Europe, Southeastern Asia, South Africa and Australia, etc. At present, Guoxin has different types of the plant for sale according to different capacities for our clients to choose from.

Different Capacity Garbage Sorting Process-3D Model Demonstration

Common sorting materials:

Light materials such as: plastic bags, woven bags, paper sheets, heavy materials (mixed materials with different density and specific gravity)

Wind separators are generally used for: household waste sorting, construction and decoration waste sorting, waste paper, plastic sorting, metal sorting

Features of Air separator:

One: Negative pressure sorting, no dust leakage.

Two: The wind speed can be adjusted steplessly to meet the needs of materials with different attributes, including high-humidity materials.

Three: Modular design, good performance and low maintenance cost.

Four: No need to configure the wind system and filter system.

Five: Choose the double-drum separation type, which can be divided into three components: light, medium and heavy.

Six: Few wearing parts, extremely low downtime for maintenance.

Seven: Integrated design of electric control machinery, plug and play at the installation site.

We have been working hard to design a brand new Construction waste crusher production line to help customers provide better production. You can use our Construction waste crushing production line, which is a fully automated Construction waste sorting machine production line, Construction waste sorting equipment production line,for various waste sorting and disposal to help customers complete their work faster.